Discover the essential techniques and tools needed for basic wood working in this comprehensive guide. Perfect for beginners and those looking to refine their skills. Unlock your creativity and bring your woodworking dreams to life.

The Ultimate Guide to Choosing the Best Drill for Woodworking

Are you a woodworking enthusiast searching for the perfect drill to enhance your craft? Look no further than “The Ultimate Guide to Choosing the Best Drill for Woodworking.” In this comprehensive guide, you’ll find all the essential information you need to make an informed decision. From understanding different drill types to considering power and speed, this article has got you covered. Get ready to take your woodworking projects to new heights as you discover the best drill that suits your needs and preferences.

Factors to Consider

When it comes to choosing the best drill for woodworking, there are several factors that you should take into consideration. Here are the key factors that can help you make an informed decision:

Power

The power of a drill is an essential factor to consider. It determines the tool’s capability to drill through different materials, including hardwoods. Higher power means the drill can handle more demanding tasks. You should look for a drill with sufficient power to meet your woodworking needs.

Speed

The speed at which a drill operates is another crucial factor to consider. Different woodworking tasks require different speeds. Having a drill with variable speed control allows you to adjust the speed to match the requirements of your project. This flexibility ensures that you can work on various materials with precision and efficiency.

Chuck Size

The chuck size refers to the opening where you insert the drill bit. The chuck size determines the maximum diameter of the bits the drill can accommodate. A larger chuck size provides greater versatility, allowing you to use a wider range of drill bits for different woodworking applications.

Corded vs. Cordless

Choosing between a corded or a cordless drill depends on your specific woodworking needs. Corded drills offer consistent power throughout your project without worrying about battery life. On the other hand, cordless drills provide greater mobility and allow you to work in areas without access to power outlets. Consider the type of woodworking projects you undertake to determine which option suits you better.

Weight

The weight of a drill can significantly impact your woodworking experience. A lightweight drill is easier to handle and maneuver, reducing fatigue during extended periods of use. However, heavier drills may offer more stability and control. It’s important to strike a balance between portability and control based on the nature of your woodworking projects.

Ergonomics

Ergonomics plays a vital role in ensuring your comfort and safety while using a drill. Consider the handle design and grip comfort of the drill. A well-designed handle with a comfortable grip can reduce strain on your hand and wrist, allowing you to work for longer periods without discomfort. Choose a drill that feels comfortable in your hand and has ergonomic features to enhance your overall woodworking experience.

Versatility

Versatility is an important factor to consider when choosing a drill for woodworking. Look for a drill that can handle a wide range of drilling applications, such as drilling holes, driving screws, and even light hammering. Additionally, consider the availability of additional features, such as built-in LED lights or adjustable clutch settings, that can enhance the versatility and functionality of the drill.

Price

Price is always a consideration when making any purchasing decision. Set a budget for yourself and look for a drill that falls within your budget range. However, keep in mind that quality and performance should be prioritized over price. Investing in a higher-quality drill may save you money in the long run, as it will be more durable and provide better results.

Brand Reputation

Brand reputation is another crucial aspect to consider when choosing a drill. Look for reputable brands known for manufacturing high-quality power tools. Established brands often have a track record of producing reliable and durable drills. Reading customer reviews and seeking recommendations from experienced woodworkers can help you gauge a brand’s reputation and make an informed decision.

Warranty

A reliable warranty is essential when investing in any power tool, including drills. A good warranty offers peace of mind and protection against manufacturing defects or premature failure. Look for drills with a warranty that covers a reasonable period of time and includes excellent customer service. This will provide you with the necessary support and assurance in case any issues arise with your drill.

Types of Drills

There are several types of drills available for woodworking, each designed for specific purposes. Familiarizing yourself with these different types can help you choose the most suitable drill for your woodworking projects. Here are the main types of drills used in woodworking:

Drill Drivers

Drill drivers are versatile drills that can perform drilling and screwdriving tasks. They are ideal for general woodworking applications, such as drilling pilot holes and driving screws into wood. Drill drivers typically come with adjustable clutch settings, allowing you to control the torque and prevent overdriving screws.

Hammer Drills

Hammer drills, also known as percussion drills, are designed for drilling into tough materials such as concrete, brick, and stone. They feature a hammering action that provides additional force and impact, making them suitable for woodworking tasks that require drilling into harder surfaces.

Impact Drivers

Impact drivers are specifically designed for driving screws and fasteners. They deliver high rotational torque, making them efficient at driving screws into wood without stripping the heads. Impact drivers are great for woodworking projects that involve extensive screwdriving, such as building furniture or assembling cabinets.

Right-Angle Drills

Right-angle drills are compact drills that feature a 90-degree angled head. They are perfect for tight spaces and hard-to-reach areas where a regular drill cannot fit. Right-angle drills are commonly used in woodworking projects that involve confined spaces, such as installing cabinetry or working in corners.

Rotary Hammers

Rotary hammers are heavy-duty drills used for drilling into masonry and concrete. They provide a powerful drilling action combined with a hammering motion, making them suitable for demanding woodworking projects that involve drilling into hard materials.

Bench Drills

Bench drills, also known as drill presses, are stationary drills mounted on a workbench or stand. They offer precise drilling capabilities and are commonly used in woodworking workshops where accuracy and stability are paramount. Bench drills are ideal for drilling repetitive holes with consistent depth and precision.

Corded vs. Cordless Drills

Drills are available in both corded and cordless versions. Corded drills require a constant power source and offer consistent power throughout your project. They are typically more powerful and well-suited for heavy-duty tasks. Cordless drills, on the other hand, rely on rechargeable batteries for power and provide greater mobility and convenience. They are ideal for woodworking projects that require flexibility and portability.

Drill Power

Understanding the power specifications of a drill is essential to ensure it meets your woodworking needs. Here are the key power-related factors to consider:

Voltage Rating

Voltage rating determines the electrical power of a drill. Higher voltage generally means more power. Typical voltage ratings for drills range from 12V to 20V for cordless drills and varying voltages for corded drills. The voltage rating should align with the tasks you intend to accomplish and the materials you will be working with.

Amperage Rating

Amperage rating refers to the electrical current drawn by the drill. Higher amperage ratings typically indicate more power. However, amperage alone does not determine a drill’s power, as voltage also plays a significant role. Consider the amperage rating in conjunction with the voltage rating to gauge the overall power of the drill.

Torque

Torque is the rotational force produced by a drill. It determines the drill’s ability to turn the drill bit into a material. Higher torque allows the drill to tackle harder materials, such as dense woods or metal. Pay attention to the torque specifications of a drill to ensure it has sufficient power for your woodworking projects.

RPM (Revolutions Per Minute)

RPM refers to the number of complete rotations the drill bit makes in one minute. Higher RPM values mean faster drilling speed. It is important to have a drill with adjustable speed control to match the RPM with the material and task at hand. Different materials require different drilling speeds to achieve optimal results.

Drill Speed

Drill speed is an important consideration as different woodworking tasks require varying speeds for optimal results. Here are the main aspects related to drill speed:

Variable Speed Control

Variable speed control allows you to adjust the drill’s speed to match the requirements of your project. It allows for precise control over the drilling speed, ensuring efficient and accurate results. Having variable speed control is particularly useful when working with different materials that require different drilling speeds.

Clutch Settings

The clutch of a drill controls the torque and prevents overdriving screws. It allows you to set the maximum torque the drill applies before disengaging. Clutch settings offer control and prevent damage to your woodworking projects. Look for drills with adjustable clutch settings to ensure you can fine-tune the torque to match the specific requirements of each task.

Chuck Size

The chuck size of a drill refers to the opening where you insert the drill bit. The chuck size determines the maximum diameter of the bits the drill can accommodate. Here are the main aspects related to chuck size:

Keyed vs. Keyless Chucks

Keyed chucks require a special tool (a chuck key) to tighten or loosen the chuck. Keyless chucks, on the other hand, allow you to tighten or loosen the chuck by hand, without the need for any additional tools. Keyless chucks offer convenience and ease of use, making bit changes quick and effortless.

Chuck Capacity

Chuck capacity refers to the maximum diameter of the drill bit that the chuck can accommodate. Consider the size of the drill bits you will be using for your woodworking projects and ensure they are compatible with the chuck capacity of the drill. A larger chuck capacity provides greater versatility, allowing you to use a wider range of drill bits.

Corded vs. Cordless

The choice between a corded and a cordless drill depends on your specific woodworking needs and preferences. Here are the advantages of each type:

Advantages of Corded Drills

Corded drills offer consistent power throughout your project. They don’t rely on batteries, so you don’t have to worry about running out of power. Corded drills are typically more powerful and well-suited for heavy-duty tasks. They are also generally lighter than cordless drills, making them easier to handle and control.

Advantages of Cordless Drills

Cordless drills provide greater mobility and allow you to work in areas without access to power outlets. They offer convenience and flexibility, as you are not restricted by a cord. Cordless drills are ideal for woodworking projects that require flexibility and portability. They are available in various battery voltages, allowing you to choose the power level that fits your needs.

Battery Type and Runtime

When choosing a cordless drill, pay attention to the battery type and runtime. Lithium-ion (Li-ion) batteries are commonly used in modern cordless drills due to their high performance, longer runtime, and minimal memory effect. Consider the amp-hour (Ah) rating of the battery, as it affects the runtime. Higher Ah ratings indicate longer battery life.

Charging Time

Charging time is an important consideration for cordless drills. Look for drills with fast charging capabilities to minimize downtime. Some drills come with rapid chargers that can charge the battery in a short time, allowing you to quickly get back to your woodworking projects. Consider the charging time and the availability of spare batteries to ensure uninterrupted workflow.

Drill Weight

The weight of a drill can significantly impact your woodworking experience. Here are the main aspects related to drill weight:

Portability vs. Control

A lightweight drill is easier to carry and maneuver, providing greater portability. If you frequently need to move around or work in different locations, a lighter drill can be more convenient. However, it’s important to find a balance between portability and control. Heavier drills can offer more stability and control while drilling.

Reduced Fatigue

Using a heavy drill for extended periods can lead to fatigue and strain on your hand and arm. Consider the duration and intensity of your woodworking tasks when choosing the weight of the drill. Opting for a lighter drill can reduce fatigue, allowing you to work for longer periods without discomfort.

Ergonomics

Ergonomics refers to the design of a drill that ensures comfort and safety during use. Here are the main aspects related to ergonomics:

Handle Design

The handle design plays a significant role in the overall comfort and control of a drill. Look for handles that are ergonomically shaped and provide a comfortable grip. Some drills come with rubberized or textured handles that offer a secure and comfortable grip, reducing strain on your hand and wrist.

Grip Comfort

The comfort of the grip is crucial for prolonged use. Consider the diameter and shape of the grip, as well as any additional features that enhance comfort, such as anti-vibration technology. Test how the drill feels in your hand before purchasing. A comfortable grip minimizes hand fatigue and allows for better control and precision during woodworking tasks.

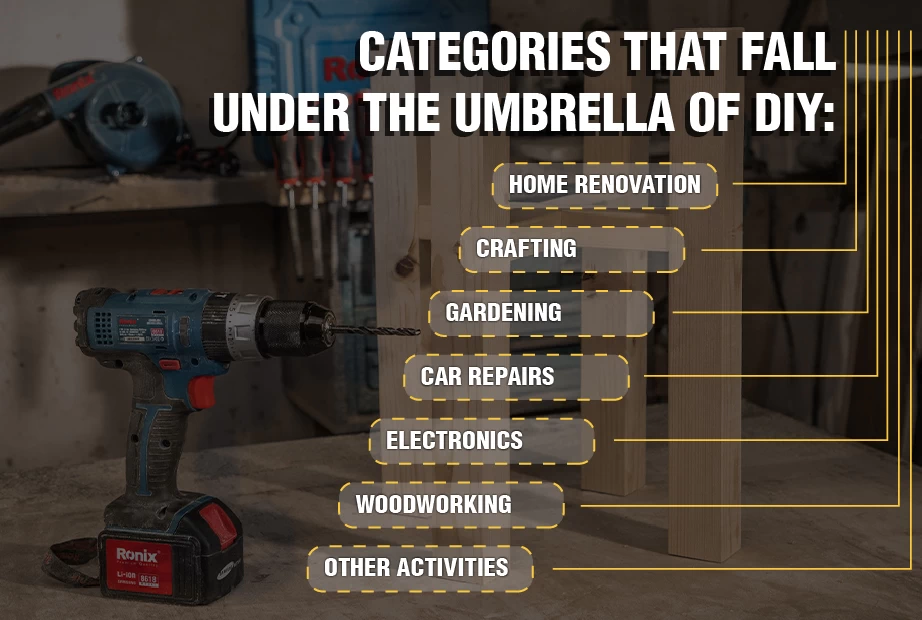

Versatility

Versatility is an important factor to consider when choosing a drill for woodworking. Here are the main aspects related to versatility:

Drilling Applications

Consider the range of drilling applications you plan to undertake in your woodworking projects. Look for a drill that can handle various tasks, such as drilling pilot holes, driving screws, and even light hammering. A versatile drill allows you to complete multiple tasks without the need for multiple tools, saving time and effort.

Additional Features

Some drills offer additional features that enhance their versatility and functionality. These may include built-in LED lights to illuminate the work area, adjustable clutch settings for precise control, or even built-in levels for accurate drilling. Consider the availability of such features and how they can benefit your woodworking projects.

Conclusion

Choosing the best drill for woodworking requires careful consideration of various factors. Power, speed, chuck size, corded vs. cordless, weight, ergonomics, versatility, price, brand reputation, and warranty are all important factors to evaluate. Assess your specific woodworking needs and preferences to determine which drill best suits your requirements. By taking the time to research and understand these factors, you can make an informed decision and invest in a drill that will enhance your woodworking projects for years to come.