Introduction to Finger Joint Woodworking

Imagine transforming a simple piece of wood into a work of art, carefully joining each piece together with precision. That’s the beauty of finger joint woodworking – a technique that allows you to create sturdy and visually stunning joints. In this article, you will discover the fascinating world of finger joint woodworking, explore its benefits, and learn how to master this craft. Get ready to unlock your creativity and embark on a woodworking journey like no other.

What is Finger Joint Woodworking?

Finger joint woodworking is a technique used to join pieces of wood together by creating interlocking finger-like projections called finger joints. These joints are typically cut into the end grain or edge of the wood, allowing for a strong and secure connection that can withstand the test of time. This woodworking technique has been used for centuries and has become an integral part of various woodworking projects, ranging from cabinets and furniture to decorative woodworking and flooring.

Definition

Finger joint woodworking involves cutting corresponding interlocking profiles into two pieces of wood to create a joint that fits together like puzzle pieces. The fingers on one piece of wood fit into the corresponding spaces on the other piece, creating a strong and stable connection. This method is particularly useful when joining long, narrow pieces of wood where other types of joints may not provide enough strength or stability.

History

The history of finger joint woodworking dates back to ancient Egypt, where this technique was used to construct furniture and other wooden structures. However, it gained widespread popularity during the 19th century in the United States, especially in the production of boxes, drawers, and cabinets. The invention of machinery and tools specifically designed for finger joint woodworking revolutionized the industry, making it easier and more efficient to produce finger jointed wood products.

Purpose

The main purpose of finger joint woodworking is to create strong and secure joints that can withstand the test of time. This technique is particularly useful for joining long and narrow pieces of wood, where other types of joints may not provide enough strength or stability. Finger joints distribute the stress evenly across the joint, making them ideal for applications where the wood is subjected to heavy loads or constant use.

Benefits

There are several benefits to using finger joint woodworking techniques in your projects:

-

Strength and Stability: Finger joints create a strong and stable connection between pieces of wood, ensuring that your project will withstand the test of time. The interlocking design of finger joints distributes the stress evenly across the joint, minimizing the risk of joint failure.

-

Cost-effective: Finger joint woodworking allows you to utilize shorter pieces of wood that may otherwise go to waste. By joining these shorter pieces together, you can create longer and stronger components, reducing the amount of new wood needed for your project.

-

Versatility: Finger joints can be used in a variety of woodworking projects, from cabinets and furniture to decorative woodworking and flooring. This versatility makes finger joint woodworking a valuable technique for both amateur and professional woodworkers.

-

Aesthetically Pleasing: Finger joints can add a unique and attractive design element to your woodworking projects. The interlocking fingers create an interesting visual pattern that can elevate the overall aesthetic of your finished piece.

Types of Finger Joints

There are several types of finger joints that can be used in finger joint woodworking. Each type has its own unique characteristics and applications. Let’s explore the most common types:

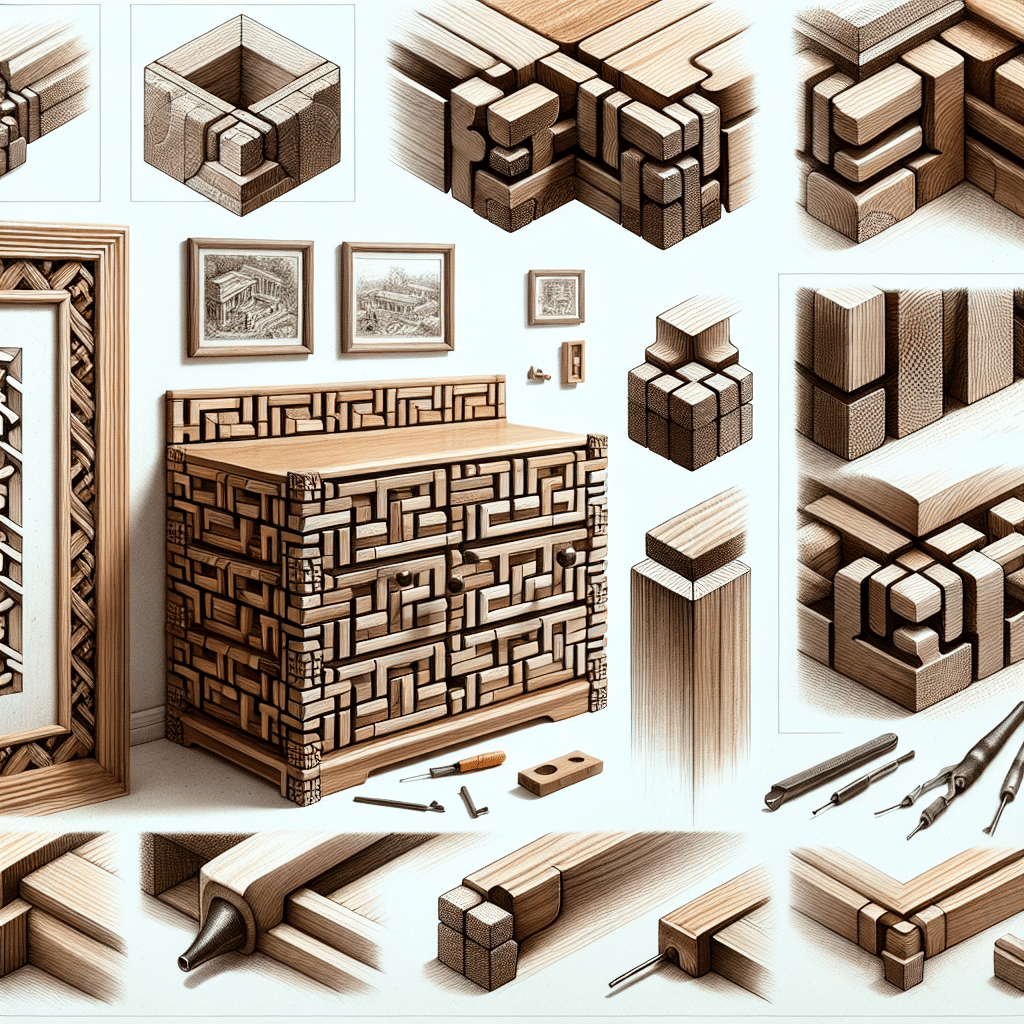

End-to-End Finger Joint

The end-to-end finger joint, also known as a box joint or comb joint, is a type of finger joint where the fingers are cut into the end grain of the wood. This joint is commonly used for joining boards together to create longer pieces or for constructing boxes and drawers. The end-to-end finger joint provides a large surface area for gluing, resulting in a strong and secure connection.

Edge-to-Edge Finger Joint

The edge-to-edge finger joint, also known as a splice joint, is a type of finger joint where the fingers are cut into the edge of the wood. This joint is ideal for joining boards together to create wider panels or tabletops. The edge-to-edge finger joint provides a seamless and flush connection, allowing for a smooth and even surface.

Corner Finger Joint

The corner finger joint, also known as a mitre finger joint, is a type of finger joint used for joining two pieces of wood at a 90-degree angle. This joint is commonly used in the construction of boxes, frames, and other angular structures. The corner finger joint provides a strong and aesthetically pleasing connection that can withstand the rigors of everyday use.

Mitre Finger Joint

The mitre finger joint is a variation of the corner finger joint, where the fingers are cut at a 45-degree angle instead of a 90-degree angle. This joint is commonly used for joining two pieces of wood at a 90-degree angle with a clean and seamless appearance. The mitre finger joint is often used in trim work, decorative woodworking, and furniture construction.

Tools and Materials Needed

To successfully execute finger joint woodworking, you will need a few essential tools and materials. Let’s take a look at what you’ll need:

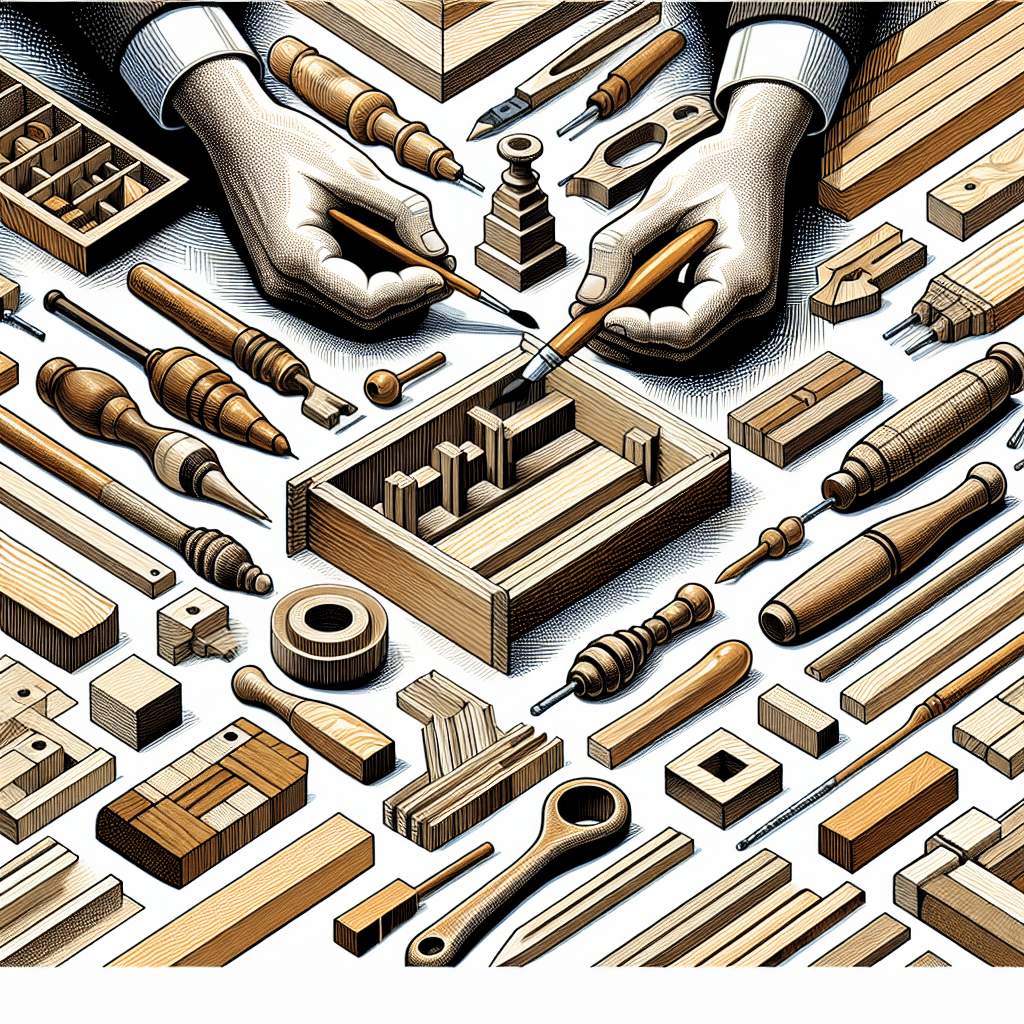

Woodworking Tools

-

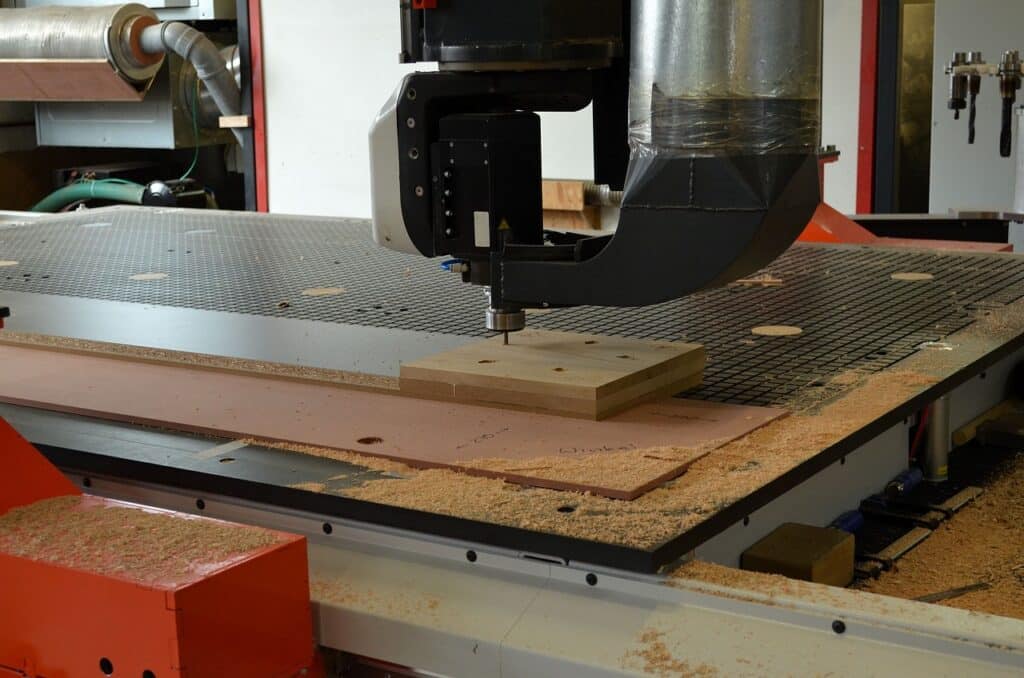

Table saw or router table with finger joint jig: These tools are essential for cutting the finger joints accurately and efficiently. A table saw with a finger joint jig or a router table equipped with a finger joint router bit will allow you to create precise and clean finger joints.

-

Dado blade or stackable dado set: A dado blade or stackable dado set is necessary for cutting the channels between the fingers of the joint. This tool ensures that the fingers have a consistent depth and width, resulting in a snug fit.

-

Miter saw or miter gauge: If you’re working on corner or mitre finger joints, a miter saw or a miter gauge attachment for your table saw will come in handy for cutting the angled ends of the boards.

-

Chisels: Chisels of various sizes are essential for cleaning up the finger joints and ensuring a precise fit. They allow you to remove any excess wood or sharp edges, resulting in a smooth and seamless joint.

Safety Equipment

-

Safety glasses: Protecting your eyes is crucial when working with power tools and sharp objects. Safety glasses will shield your eyes from flying debris and prevent any potential injuries.

-

Ear protection: Power tools can produce high levels of noise, which can be damaging to your hearing. Wearing ear protection, such as earplugs or earmuffs, will help reduce the risk of hearing damage.

-

Dust mask or respirator: Woodworking produces a significant amount of sawdust and airborne particles. Wearing a dust mask or respirator will protect your lungs from breathing in these particles and prevent respiratory issues.

Wood Materials

-

Hardwood or softwood boards: The type of wood you choose will depend on the specific requirements of your project. Hardwoods like oak, maple, or walnut are commonly used for their durability and aesthetic appeal, while softwoods like pine or cedar are more affordable and easier to work with.

-

Boards of appropriate thickness and width: The dimensions of the boards will depend on the size of the finger joints you plan to create. Ensure that the boards are flat, straight, and free of any defects or imperfections.

Glue

- Wood glue: Quality wood glue is essential for creating a strong and durable bond between the finger joints. Look for glue specifically designed for woodworking, such as PVA (polyvinyl acetate) glue, which provides excellent adhesion and dries clear.

Step-by-Step Process

Now that you have all the necessary tools and materials, let’s walk through the step-by-step process of finger joint woodworking:

Preparing the Wood

-

Select the appropriate wood for your project, taking into consideration its strength, durability, and aesthetic qualities. Ensure that the boards are flat, straight, and free of any defects or imperfections.

-

Mill the boards to the desired thickness and width using a table saw or planer. Make sure that the boards are parallel and of equal dimensions for accurate and consistent finger joint joints.

Measuring and Marking

-

Measure the desired length and width of the finger joint using a measuring tape or ruler. Mark these dimensions on the boards using a pencil or marking knife.

-

Mark the locations for the finger joints on the edges or end grain of the boards, ensuring that the joints are evenly spaced and aligned.

Cutting the Finger Joints

-

Set up your table saw or router table with the appropriate finger joint jig or router bit, ensuring that it is aligned and securely in place.

-

Adjust the height, depth, and width of the dado blade or stackable dado set to match the dimensions of the finger joint.

-

Position the first board against the fence of the table saw or router table and make the first cut. Repeat this process for all the required finger joints, ensuring that the cuts are accurate and consistent.

Dry Fitting

-

Test the fit of the finger joints by dry fitting the boards together. The joints should fit snugly without any gaps or misalignments.

-

Use a chisel to make any necessary adjustments, such as removing excess material or refining the joints for a perfect fit.

Gluing the Joints

-

Apply a thin and even layer of wood glue to both sides of the joints, ensuring complete coverage.

-

Join the boards together, aligning the finger joints precisely. Apply even pressure to ensure a tight bond between the joints.

Clamping and Finishing

-

Clamp the boards together using woodworking clamps or pipe clamps to apply even pressure and hold them securely in place.

-

Wipe away any excess glue with a damp cloth or sponge. Allow the glue to dry according to the manufacturer’s instructions.

-

Once the glue is fully cured, remove the clamps and clean up any remaining glue residue. Sand the jointed area to ensure a smooth and seamless finish.

Tips for Successful Finger Joint Woodworking

To ensure successful finger joint woodworking, keep the following tips in mind:

Choose Suitable Wood

Select wood that is appropriate for your project, taking into consideration its strength, durability, and aesthetic qualities. Different projects may require different types of wood, so choose accordingly.

Sharp and Properly Set Tools

Ensure that your tools, including the saw blades and chisels, are sharp and properly set. Dull or improperly set tools can result in inaccurate cuts and poor-fitting joints.

Accurate Measurements

Take precise measurements and mark them clearly on the wood. Accuracy is crucial for creating tight-fitting finger joints that will result in strong and stable connections.

Test Cuts

Before cutting the actual finger joints, make test cuts on scrap pieces of wood to ensure that the settings and adjustments on your tools are accurate. This will help you avoid costly mistakes and achieve the desired results.

Proper Glue Application

Apply an even layer of wood glue to both sides of the joints to ensure a strong and secure bond. Avoid using too much glue, as excess glue can cause a mess and affect the overall quality of the joint.

Appropriate Clamping Techniques

Use woodworking clamps or pipe clamps to apply even pressure and hold the joint together while the glue dries. Ensure that the clamps are positioned correctly to prevent misalignment or distortion of the joint.

Sanding and Finishing

After the glue has dried, sand the jointed area to achieve a smooth and seamless finish. This step is essential for ensuring an aesthetically pleasing result and removing any sharp edges or imperfections.

Common Challenges and Troubleshooting

Despite following the proper techniques, finger joint woodworking can sometimes pose challenges. Here are some common challenges you may encounter and troubleshooting tips to overcome them:

Gaps in Joints

If you notice gaps between the fingers of the joint, it may indicate that the joints were not cut accurately or the pieces of wood were not properly aligned. To fix this issue, carefully adjust the joints by refining the cuts or removing excess material with a chisel.

Misalignment

Misalignments can occur if the boards are not properly positioned or the joints were cut with incorrect measurements. To fix misaligned joints, carefully disassemble the jointed pieces, realign them, and then reassemble with fresh glue.

Weak Joints

Weak joints may occur if the glue was not applied evenly or if the jointed pieces were not clamped tightly enough during the drying process. To strengthen weak joints, remove the jointed pieces, clean them thoroughly, reapply fresh glue, and clamp them securely while the glue dries.

Splintering

Splintering may occur during the cutting process if the wood is brittle or if the blades and tools are dull. To prevent splintering, use sharp tools and blades, and make sure to support the wood adequately during the cutting process.

Difficulty Joining Angles

Joining angles, such as in corner or mitre finger joints, can be challenging due to the need for precise measurements and cuts. Take extra care when measuring and marking the angles, and make test cuts to ensure accuracy before cutting the actual joints.

Applications of Finger Joint Woodworking

Finger joint woodworking finds a wide range of applications in various industries and projects. Here are some common applications:

Cabinetmaking

Finger joints are commonly used in the construction of cabinets, both for the main structure and the drawers. The strength and stability provided by finger joints make them ideal for supporting heavy loads and withstanding constant use.

Furniture Construction

Finger joints are found in various furniture pieces, including chairs, tables, and bookshelves. They provide the strength and stability necessary for furniture to withstand everyday use and the test of time.

Decorative Woodworking

In decorative woodworking, finger joints are often used to create visually appealing patterns and designs. They add an interesting element to boxes, picture frames, and other decorative pieces.

Door and Window Frames

Finger joints are frequently used in the construction of door and window frames. The durability and structural integrity of finger joints make them an excellent choice for supporting the weight and movement of doors and windows.

Flooring

Finger jointed wood is commonly used in flooring due to its stability and ability to withstand heavy foot traffic. The joints ensure a tight and secure fit between the floorboards, resulting in a smooth and durable surface.

Comparisons with Other Joinery Techniques

While finger joint woodworking is a versatile and widely used woodworking technique, it is important to consider other joinery techniques for different applications. Here are some comparisons:

Dovetail Joints

Dovetail joints, known for their interlocking wedge-shaped fingers, are often considered the gold standard for joint strength and aesthetics. Dovetail joints are commonly used in high-end furniture and cabinetry where aesthetics and craftsmanship are paramount.

Mortise and Tenon Joints

Mortise and tenon joints are strong and durable, making them suitable for heavy-duty applications such as timber framing and table construction. They provide excellent joint strength and rigidity but require precise cutting and fitting.

Biscuit Joints

Biscuit joints are quick and easy to create, making them popular in cabinetmaking and carpentry. They are often used to join flat panels together or align and strengthen miter joints. Biscuit joints are not as strong as finger joints but provide sufficient strength for many applications.

Dowel Joints

Dowel joints are similar to finger joints in terms of their strength and durability. Dowels can be used to join pieces of wood together by drilling holes and inserting wooden or metal dowels. Dowel joints are commonly used in furniture construction and cabinetmaking.

Finger Joint Woodworking in Contemporary Design

Finger joint woodworking has adapted to the demands of contemporary design, incorporating modern trends and techniques. Here are some examples of how finger joint woodworking is utilized in contemporary design:

Modern Furniture Trends

Finger joint woodworking techniques are incorporated into modern furniture designs, embracing minimalistic aesthetics, clean lines, and sleek finishes. This combination of traditional woodworking techniques with contemporary design results in functional and visually appealing furniture pieces.

Integration with Other Materials

Contemporary design often blends multiple materials to create unique and innovative pieces. Finger joint woodworking lends itself well to integration with materials such as metal, glass, and acrylic. This combination of materials adds complexity and visual interest to the finished product.

Minimalist Aesthetics

Finger joint woodworking is often used to create minimalist designs that focus on simplicity and functionality. The clean and seamless finger joint connections contribute to the sleek and uncluttered aesthetics that are popular in contemporary design.

Sustainable Design

Finger joint woodworking aligns well with the principles of sustainable design. By utilizing smaller, otherwise wasted pieces of wood, finger joint woodworking reduces waste and promotes resource efficiency. This technique also allows for the use of reclaimed or salvaged wood, further reducing the environmental impact of the project.

Conclusion

Finger joint woodworking is a versatile and widely used technique that offers strength, stability, and visual interest to a variety of woodworking projects. Whether you’re constructing cabinets, furniture, or decorative pieces, finger joints provide a strong and secure connection that can withstand heavy loads and constant use. By following the step-by-step process, utilizing the right tools and materials, and incorporating the provided tips and troubleshooting techniques, you can achieve successful finger joint woodworking and create beautiful and durable wood creations. Explore the applications of finger joint woodworking, experiment with different joint types, and let your creativity shine in your woodworking projects. With finger joint woodworking, the possibilities are endless!